Scientists print titanium cube 50% stronger than aerospace alloy

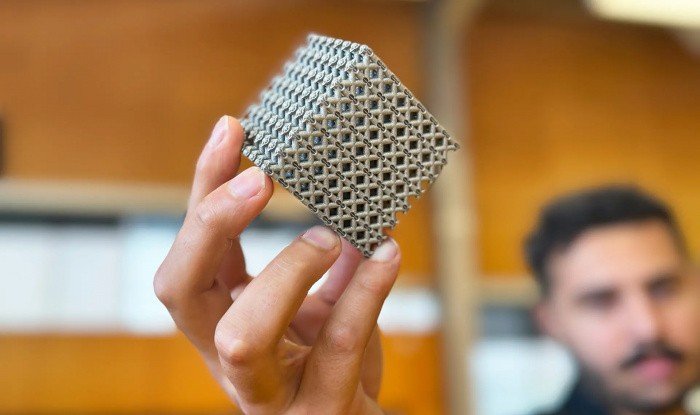

Australian researchers at RMIT have developed a unique lattice structure that is almost one and a half times stronger than the cast magnesium alloy WE54 used in the aerospace industry. At first glance, it is very complex, but the scientists say that if you have a 3D printer to make it, it can be relatively simple.

The starting point for the work was hollow strut structures. The team was inspired by water lilies and coral. To be successful, they had to look closely at all possible ways to reduce the stress concentration of the materials at their junctions. Lead author of the study, Professor Ma Qian, says that in cellular structures, stresses should be evenly distributed, but in most topologies, only half of the material works against compressive loads.

The researchers needed to strengthen the tubular lattice. They did so by overlaying a second lattice and adding a thin X-shaped transverse reinforcement. This made the load distribution more uniform, which was confirmed in tests. Importantly, the lattice can be scaled to produce parts of the desired shape and size – the possibilities are limited only by the printer used. The material also showed good heat resistance – 660°F. If a heat-resistant titanium alloy is used in the design, this can be increased to 1110°F.

Several applications of the technology are already apparent. First, the structure can be used in the production of aircraft and spacecraft parts. In addition, it could be a breakthrough for medicine – the material is excellent for bone implants. Professor Ma Qian believes that in time it will be available for mass use in a variety of fields.

You may be interested: Albedo Space satellites will be able to photograph anyone right from orbit